- Joined

- Jun 23, 2010

- Messages

- 44,400

- Reaction score

- 29,176

- Location

- Frederick, Maryland

- Showcase(s):

- 1

- Hardiness Zone

- 6b

- Country

How darn cool! What a neat idea.

....................... if this works.................................

I"m assuming you will have your pond water circulating through those bogs? The intake is easy enough, but the return lines could be more problematic if you don't want the water to overflow the troughs. How do you plan to design the return water ports?

You do lovely work Timothy.

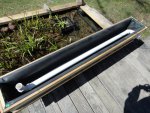

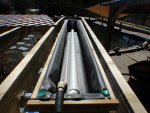

I haven't quite decided which way I want to go, but have two methods in mind;

1. On the opposite end of the trough from the supply (pond side), I may cut the inboard side of each trough down about two inches for a distance of four or five inches and fasten a flat-sided funnel to the outside with the EPDM over-lapping the edge. (Very much like I did with the above-ground bog.)

View attachment 90555 View attachment 90556

Each bog funnel pipe would have a removable clamped section that would join at a tee fitting behind the pond-facing header, and from there it's just a matter of piping with 1 1/2" PVC keeping it all tucked up as out-of-sight as I can before I reach the down pipe. At the base of the down pipe there will be a transition from hard pipe to direct bury 1 1/2" flex hose from there to the pond. I want to use the flex hose because it won't be buried that deep, and I don't want frost to crack/break the PVC. I'll blow out and cap the hose in the winter.

2. The second option (most likely) is to pierce the lower inboard sides of each trough and insert a 1 1/2" close nipple with a 90 degree elbow inside the box facing forward. A 60" +/- piece of pipe, and at the end of this will be a 90 facing up. The pipe coupling on the outside of the box needn't be sealed, but the 90 on the inside will be drawn up tight (by the outside fitting) to the EPDM with a slathering of that evil black stuff out of a tube to prevent any leakage. A short section of PVC pipe will come up to the surface (at whatever level is decided) allowing the return water to simply "fall" into the open surface drain, through the 90 hence to the tee and back as in #1 to the down pipe etc.

I'm leaning towards #2 as it would be less hassle and not exposed to wind before entering the return pipe. I intend to put a dome-shaped screen above the stand pipe with a diameter of probably 6-7" so should a leaf or something obscure one area there would be sufficient area remaining to prevent the bog overflowing.

In a few days I should have these parts installed and I'll post a couple photo's of how it worked out.

Whichever way you decide your outlet must be at least twice the size of your inlet since this will be gravity feed outflow. It may need to be much larger depending on your flow rate.

Are you sure about the Lava Rock? I am cautious as to whether it will supply the support and anchoring for the plants that will be needed.

Want to reply to this thread or ask your own question?

You'll need to choose a username for the site, which only take a couple of moments. After that, you can post your question and our members will help you out.