I currently use a shop vac to do my spring clean of the pond. It works, but it could be better. What I don’t like is that if you don’t pull the vac hose out before it fills up, the ball will kick in and stop suction and any water / muck in the hose will rush out back into the pond. If this happens you instantly loose visibility, and it is more difficult to clean. I want to make a vacuum that will run continuous so this won’t happen.

Basically what I want to make is an inline system, and here is my thinking.

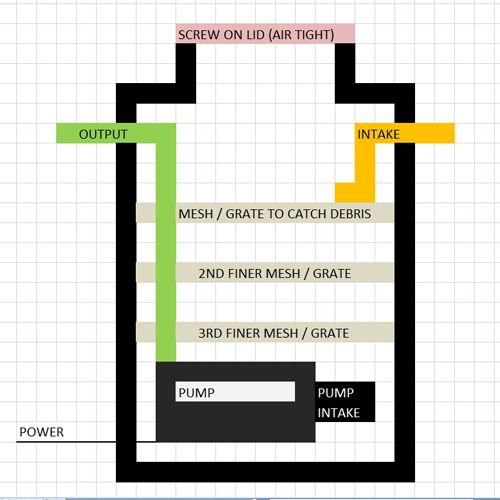

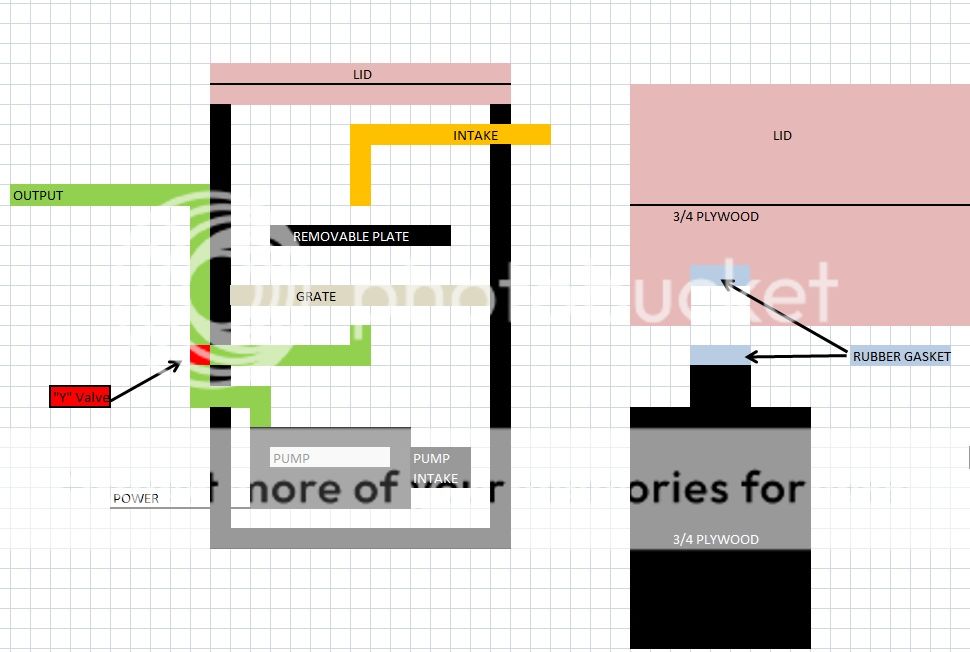

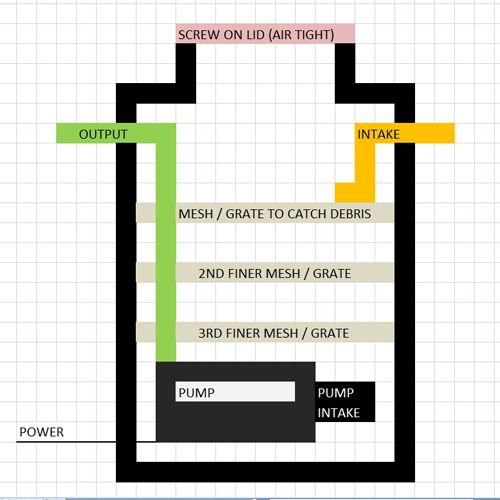

I have a 1200 gph pump I am not using that I think could work for this. I start with a barrel with a screw on lid maybe 10 or 15 gallon. I would drill two holes in the barrel, a input & output. The intake would come through the side and a size I could connect my vac hose to in order to vacuum. The output would connect to the pump, up and out, where it would connect to a length of hose to drain into the garden. I could avoid the debris hitting the open intake of the pump by adding separate layers of grates until it reached a small size where it could be sucked up and dumped into the garden.

The input/output and power line would have to be glued tight so unit won’t loose pressure. I figure if the barrel does not leak the water should pass right through.

I would bring this out and connect the vac hose and the exit hose. I would then bring out a garden hose and fill the barrel through the exit hose (to prime it). At that point I should be able to put the vac end in the pond and the exit hose in the garden and start it up.

Anyone see any major flaws with this idea? I realize leaves would clog this up, but between the skimmer and my pool net, my issue is smaller material.

Basically what I want to make is an inline system, and here is my thinking.

I have a 1200 gph pump I am not using that I think could work for this. I start with a barrel with a screw on lid maybe 10 or 15 gallon. I would drill two holes in the barrel, a input & output. The intake would come through the side and a size I could connect my vac hose to in order to vacuum. The output would connect to the pump, up and out, where it would connect to a length of hose to drain into the garden. I could avoid the debris hitting the open intake of the pump by adding separate layers of grates until it reached a small size where it could be sucked up and dumped into the garden.

The input/output and power line would have to be glued tight so unit won’t loose pressure. I figure if the barrel does not leak the water should pass right through.

I would bring this out and connect the vac hose and the exit hose. I would then bring out a garden hose and fill the barrel through the exit hose (to prime it). At that point I should be able to put the vac end in the pond and the exit hose in the garden and start it up.

Anyone see any major flaws with this idea? I realize leaves would clog this up, but between the skimmer and my pool net, my issue is smaller material.