Yes, swimming pool installer is what you want. There really is no such thing as a pond builder for concrete ponds, at least I've never heard of one. Finding a pool installer with any pond experience can be hard, maybe impossible. Basically you just call every pool installer in the yellow pages and ask if they have ever built a pond.

There will also be people out there wanting to start a pool building business. They might take a shot at it. But of course they may barely know how to build a pool let alone a pond.

Here's a thread in another forum I've been reading on

a guy in the same boat as you. Lot's to learn from his experience.

What the township told you is insane. I've lived in several states, many cities, and it's always been the same, basically the opposite of what you were told. Normal code is any water feature deeper than a set amount, I've seen 18" to 24", is treated exactly the same. They don't care if it's a swimming pool, pond, or wishing well. For example I've never seen code that requires a filter on a swimming pool. If you add a filter then yes it's installation is cover by code. Unless you're in a town that they don't care about anything that pond would be covered by code.

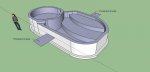

Next, the pond/pool you're building is no normal pool. Like you said, most pool installers don't have to deal with forms, at least the kind you'd need. Bedrock presents more problems because a lot of pipes are normally run under the pool. So you're limited to high end pool builders.

The contractors not calling back...You expected a contractor to return a phone call? I have heard stories and rumors of contractors calling back but I sure have never experienced it. You need to talk to a swimming pool sales person out of the yellow pages. They get paid on commission. They know how to promise you the moon and then try to figure out the details later.

The biggest rub is swimming pool builders don't generally know much about ponds. If you read the thread in the link you will see that you need to be the on site pond expert. You can also connect with the local Koi club. Some of them may have built such a pond and can recommend someone.

Contractors aside...20" above grade is nothing. You can certainly do that with block. I've gone 3' above grade with block. You aleady have as good a foundation as there ever was, bedrock. Drill some holes for vertical rebar, epoxy in place and dry stack bock. Every course above grade gets horizontal rebar. Use bond beam block for everything. Fill all block voids with concrete. Use a liner and forget the spray on what it was you said.

You have curved walls. They can be done with block too, maybe half blocks. Lay the first course, fill with concrete maybe half full and let set for a couple of days. This first course can now be used to build the form. Rip 1/8" Luan plywood into 12" widths. Press one strip against the inside of the first course and another strip on the outside and clamp. You may want to dry stack another course just as something to clamp to. Use a urethane wood glue to bond additional Luan strips, building to at least 1/2" thick. Let the glue cure for 24 hours. Now as you build each course you can clamp the form on the outside and inside and fill the block with concrete. The concrete will fall out the gaps caused by curving the block and be stopped by the form. You can even skip the inside form if you like. Let the concrete set up for a couple of hours and repeat for each course. The block keeps most of the pressure off of the form, plus you're only doing one course at a time. So blowing out a form is not much of a risk.

Not to bust your chops but some of the things you're saying doesn't make sense to me, like "allow the concrete to set up for 6 months". Stuff like that can cause a contractor to bail. I've done it many times and it's not something you can tell the customer because they'd just get mad. If a customer is saying a lot of things and it's clear they think they know more than the actually do it's a no win situation. There's no way I will ever be able to make the customer happy. If I follow the instructions to the letter the result is a complete wreck and I get blamed. If build correctly against the customer's instructions they get mad as hell. Explaining stuff doesn't work either because nothing makes sense to them. I'd rather they be mad because I refused to bid than end up in court. I don't know you, don't know the story, just saying.

The foam thing, that's pretty wild. How much are you willing to spend? Sounds like a lot.