I am in the process of purchasing all my plumbing supplies for this job. What is the best type of PVC cement to use? I am not a plumber, so I just need to know the best method of joining all my PVC together.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY biofilter

- Thread starter lollyfrog

- Start date

brand doesn't matter. it's sold where ever you buy PVC pipe in a small container with a brush attached to the lid of the container. Applying it is easy just remove the lid and use the brush to smear some on the inside of the pipes you are joining. You don't want to apply too much since the goal is not to have it squeeze out and overflow when you attach the pipes. The cement basically reacts chemically with PVC to melt it with heat.

You need to buy two cans. First is the primer, this softens the pipe to prepare them for the cement. Then you apply the glue. Oatey is the most common brand seen.

Any home improvement store sells it. The primer is purple usually and the cement is typically clear. I like the heavy duty cement that is in the green can, but pretty much any of them work.

You need to work quickly with the cement and fit the pieces together fast so they don't dry. Also, keep in mind that you don't need to glue any elbows or pipes in your barrels. It is best to leave those unglued so that you can remove them just in case. You can use PL roofing and flashing caulk for the main pipes screwing into your barrel such as the bulkheads. Not sure what you're using for pipe exiting or entering the barrel.

Any home improvement store sells it. The primer is purple usually and the cement is typically clear. I like the heavy duty cement that is in the green can, but pretty much any of them work.

You need to work quickly with the cement and fit the pieces together fast so they don't dry. Also, keep in mind that you don't need to glue any elbows or pipes in your barrels. It is best to leave those unglued so that you can remove them just in case. You can use PL roofing and flashing caulk for the main pipes screwing into your barrel such as the bulkheads. Not sure what you're using for pipe exiting or entering the barrel.

I've never used primer. The cement (Oatey brand) is the solvent, no primer needed.

You can use the cement by itself if you so choose, I guess. But most folks use the primer first as it gives some grip to the cement on the pipe and softens the pipe a tad. Oatey recommends using primer.

It's sort of like painting a wall, you don't need to use primer before you paint, but it sure is recommended you do so.

There is a reason that the primer is bright purple, by the way. It's so cities/town inspectors can prove that a plumber/builder is using the primer--which most jurisdictions require you do. Builders were trying to skip using the primer to save the time/expense, so the purple color is a signal to inspectors that the proper primer has been used.

To each his/her own, of course. But I see no reason to skip this step and it makes for a better seal.

It's sort of like painting a wall, you don't need to use primer before you paint, but it sure is recommended you do so.

There is a reason that the primer is bright purple, by the way. It's so cities/town inspectors can prove that a plumber/builder is using the primer--which most jurisdictions require you do. Builders were trying to skip using the primer to save the time/expense, so the purple color is a signal to inspectors that the proper primer has been used.

To each his/her own, of course. But I see no reason to skip this step and it makes for a better seal.

Just got back from the hardware store during lunch. Got a cleaner and the cement, will the cleaner be like a primer? Also, 3 sections of 2" pipe and all the fittings, including two ball valves each costing $21.99 came to a total of $156.00. Holly Cow, I thought this DIY stuff was suposed to save money!  I am looking forward to getting started in my garage. I am going to use two compression connectors to connect the system to my pond. One coming in, and the other going out, so I can remove the entire system for cleaning or repair if needed. Those were about $9.00 each.

I am looking forward to getting started in my garage. I am going to use two compression connectors to connect the system to my pond. One coming in, and the other going out, so I can remove the entire system for cleaning or repair if needed. Those were about $9.00 each.

Okay, here I go with more questions. Has anyone here ever built a waterfall manifold? That is where you divide the flow back to your pond so that it flows out of several diffent hoses. Currently, I have a 2" pip that is split by a T into two 1½ flexible hoses to my falls. Does anyone have any advice on this subject?

Thanks!

Mike

Thanks!

Mike

I don't know what brand you've purchased. If it's Oatey, it should very clearly say primer on the can. It's a purple can and you can't mistake it. Unless your brand says cleaner and primer, it is not the same.

Ball valves can be expensive in the hardware store versus the big box chains, but they are much better quality. They will be more expensive for sure. I have a bunch of compression connectors on my pond as well, and they are very useful as you can remove them when necessary.

I'm not clear on what you're asking about regarding the manifold. I have several that i've created with a Y pvc pipe (wye), they don't have as hard as an angle as a tee so you get less friction. The big box stores also sell y's as compression fittings too, but I think the largest size might be 1 1/2 inches (can't remember if they make a 2" wye). You simply put a ball valve on one of your divided pipes and you can control the waterflow. You don't need two ball valves, just one is enough to force more water through one side rather than the other.

Ball valves can be expensive in the hardware store versus the big box chains, but they are much better quality. They will be more expensive for sure. I have a bunch of compression connectors on my pond as well, and they are very useful as you can remove them when necessary.

I'm not clear on what you're asking about regarding the manifold. I have several that i've created with a Y pvc pipe (wye), they don't have as hard as an angle as a tee so you get less friction. The big box stores also sell y's as compression fittings too, but I think the largest size might be 1 1/2 inches (can't remember if they make a 2" wye). You simply put a ball valve on one of your divided pipes and you can control the waterflow. You don't need two ball valves, just one is enough to force more water through one side rather than the other.

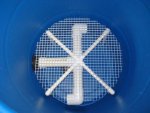

Well, I finally got the project finished with some help from my friends, and a local plumber. I had some leaking problems at first, but I was told to take it all apart and use both teflon tape and plumber's putty. That did the trick, but was a pain in the you know what. So after a leak test, I had some help putting the entire system in place, and I plumbed it into my existing plumbing. Hope you like the pictures... This is my first barrel where the water enters the filter system.

Attachments

Even MORE pictures...

You can see where I have the water coming into the system in the third photo, and out in the 4th photo. I had to use a lot of 90º elbows unfortunately. Also, you can see the rubber feernco union I used after I had to take it all apart. You can also see that my concrete blocks are sitting on my old bio material, lava rocks. I am going to use one cubic foot of that expensive "K" straw-like material that has the ridges on the sides, and several bags of Bacti-Tiwst. I did use some of that PL roofing and flashing sealant on the bottom drains, on the outside, JUST IN CASE!

You can see where I have the water coming into the system in the third photo, and out in the 4th photo. I had to use a lot of 90º elbows unfortunately. Also, you can see the rubber feernco union I used after I had to take it all apart. You can also see that my concrete blocks are sitting on my old bio material, lava rocks. I am going to use one cubic foot of that expensive "K" straw-like material that has the ridges on the sides, and several bags of Bacti-Tiwst. I did use some of that PL roofing and flashing sealant on the bottom drains, on the outside, JUST IN CASE!

Attachments

koiguy1969

GIGGETY-GIGGETY!!

good job.. looks like it work, but i still would have top fed my first barrel down the center to the swirl bars... so make sure you have your input line protected from backflow with a check valve because if you lose power you will almost totally drain that barrel back in the pond. feeding from the top with a simple tee adapter connection at the top of the down pipe instead of an elbow eliminates that possibilty by allowing a beak in the syphon.

I totally understand, and that has happened to me before with my other system, which by the way is being used here at my school in the Ag shop, and it is working better than ever before.

I didn't install a check valve, only because I thought it would slow down my flow rate too much. I can do this in my skimmer area right after the water leaves the pump. What are your thoughts on check valves? Is there a certain kind that is better than others? When I clean out my skimmer and pump, I just quickly put a cap on the end of the pipe to prevent back flow.

Thanks for the KUDOS!

I didn't install a check valve, only because I thought it would slow down my flow rate too much. I can do this in my skimmer area right after the water leaves the pump. What are your thoughts on check valves? Is there a certain kind that is better than others? When I clean out my skimmer and pump, I just quickly put a cap on the end of the pipe to prevent back flow.

Thanks for the KUDOS!

koiguy1969

GIGGETY-GIGGETY!!

for skimmer / pump clean out purposes (or replacing pump) i would have put a ball valve right by the pump that way you close it before the disconnecting and you lose virtually no water at all.

Looks good Schroeder! I would like to do some barrel filters myself. You are giving me the inspiration that I can do this. Of course my Hubby would build it for me!

Ask a Question

Want to reply to this thread or ask your own question?

You'll need to choose a username for the site, which only take a couple of moments. After that, you can post your question and our members will help you out.

Forum statistics

Latest Threads

-

Turtle Pond Red Mangrove victim of success!

- Started by Stephen Noble

-

Concrete lined pond and plants - please advice to very newbie

- Started by John Tired

-

Ultra sieve 111

- Started by LAK

-

Fungus?

- Started by Ana

-

He attacks again!

- Started by Chumley

-

Magnolia Bokeh

- Started by RobAmy

-

Spring has sprung in Tennessee -pic heavy

- Started by Hound Heaven

-

Whats next

- Started by Run91

-

Rapid change in "surface" algae

- Started by chibae

-

Pond Waterfall Setup Help

- Started by Acedink