Howard! OMG

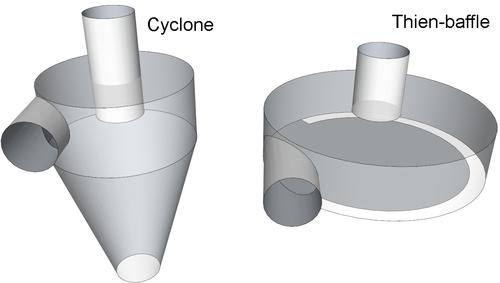

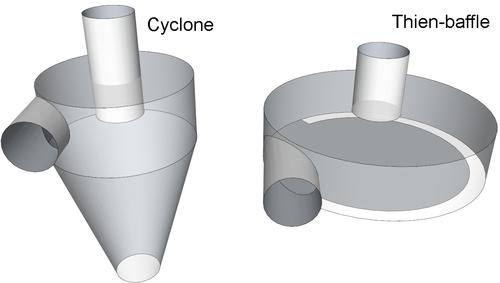

That's IT! That's IT! The Thien-baffle is exactly what I am designing!

The difference is that the cylinder atop is much longer (taller) with multiple chambers inside it. And it is square, not cylindrical and the water passes vertically through the multiple chambers.

This square design I have adapted purposely to make fabrication easier. I can make four sides to form a box from 1/2" poly plastic and router slots for "shelves" in the sides to set the baffles on.

Then I can bolt the sides of the box together at the corners with small SS fasteners. With this construction, I can disassemble it and change the baffles out with different patterns and designs and hole sizes if operation performance dictates. Trying to think ahead there.

The large chamber area at the bottom is the same with the water entering in a manner to create a circular flow of the water around the outer perimeter of the barrel. I have also added a 12" diameter PVC pipe of 6-7" height to be inserted in the center of the bottom chamber. This creates two concentric chambers in the lower portion of the barrel. This short piece of large diameter PVC pipe would be drilled full of holes to allow the water to pass through. The water flows around the outside of this pipe, first. The bottom rim of this piece would have notches cut to allow the water to pass under it so that, when drained, the detritus collected in the outer chamber can rinse out, too. The drain will be in the center of the barrel on the bottom This PVC pipe section also provides mechanical support for the structures above, because they will be somewhat heavy.

The bottom chamber would be approximately 6-7 inches deep and closed off from the upper area of the barrel except in the very center where the upper cylinder (box) attaches. What separates the lower chamber from the chambers above is a 21.5" diameter x 1/2" thick poly plastic disc that I cut to fit the inside of the barrel. The center 10-12 inches would be perforated with 1/4" holes to allow the water to escape into the upper, smaller diameter cylinder (box). The central, upper cylinder (box) would be approximately 10 inches square and 26-28 inches tall. The water would pass up through the central cylinder and overflow at the top into the outer perimeter of the barrel.

From there, the water could exit the barrel via pvc pipe for further conditioning. The open chamber on the outside of the upper cylinder could provide some additional settling, albeit minor. OR... I could use that space to aerate the water or it would just serve as a "reservoir". Like in your pix where you have the plants in the "hat".

Possiby at the exiting point, I thought I might use a 300 micron SS mesh screen filter. Fabricating it to be easily removed and cleaned with a garden hose. But, I'll have to evaluate that point further when I get there.

It is just awesome to see that diagram that you posted of the Thien-baffle! Basically, someone else had envisioned the same concept at some time. I was "engineering" this design from scraps of poly plastic that I get from work and discarded poly barrels and trying to make it "do" something beneficial for me. It's uncanny that I sort of landed on a similar concept by shear accident, or trial and error. I am thinking that it is going to work! I love this stuff!

EDIT: Of course, this baffle, the Thien baffle, was designed for a shop-vac application. But, I see it functioning in the same basic concept here for water separation. The mechanics are so similar.

Catfishnut