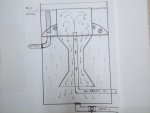

I have been working on many designs for my water filtration system over the past couple of years and developed this "sediment / solids separator" most recently.

I would like to know your opinion of this current design. It is based upon Paul Van Der Werf's "radial flow" filter for an aquaponics system, but I have some troubles with his nomenclature for such a filter (or separator). I keep reviewing his videos from the EarthanGroup site and what they are presenting there do not fit my concept of a "radial flow" device. From the videos that I have reviewed, it seems to me that it is a vertical "AXIAL FLOW" device. That is another item for later discussion, but what I want to present to you is what I personally call a VERTICAL AXIAL SEPARATOR. The principle of the system is to drop out the muck and heavier solid matter exiting the pond or fish tank as a "prefiltration" unit, before routing the water to the other stages of the filter system (BIO-CONVERSION units).

My theory of the equipment operation is thus:

Water from the pond will gravity feed into the barrel chamber and rises up through a 2"-3" PVC tube to a level where the outlet of the tube meets a stilling "vat" or chamber that is open at the top - and bottom. The water does not overflow this stilling chamber, it slows in velocity and must redirect its flow to fall towards the bottom of the barrel, taking the heaviest sediments and debris with it. At the bottom of the barrel, the waterlogged and heavier sediments will collect and accumulate around the evacuation port (the drain) and can be exhausted when necessary by opening the valve.

Cleaner water, or that water that has lost its "load" must eventually rise to the outlet port, however, on its way, it will meet a baffle plate which will be constructed with several circular holes. These holes will be screened off with 300 micron SS fitler panels. Once the water passes through and reaches the top level of the barrel, it may pass through a perforated PVC standpipe, wrapped with finer mesh, cleanable, nylon mesh fabric (maybe 100 microns). This mechanical filter as well as the SS panels will all be designed to be easily removed and washed clean at periodic intervals - but the main duty of this first stage barrel is to "drop the muck" before it even gets to these fitler screens.

The principle of operation is exactly what Paul van der Werf explains in his radial flow filter videos, so I am applying that principle to the overal function of this barrel filter, yet adding my own DIY components to make it fit my own ideas.

The outlet or effluent water from this barrel filter will feed into the second mechanical filtration stage (another 55 gallon barrel). In that stage, I will incorporate ten - 50 micron nylon mesh filter socks to finish the job of large solids removal. These filter socks will also be easily removed and cleaned with a garden hose.

If you can discern the filter operation through my verbal description and the drawing I attached, let me know if you think that this filter is a good design or not.

Thanks,

Catfishnut

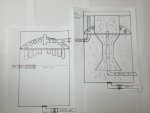

I would like to know your opinion of this current design. It is based upon Paul Van Der Werf's "radial flow" filter for an aquaponics system, but I have some troubles with his nomenclature for such a filter (or separator). I keep reviewing his videos from the EarthanGroup site and what they are presenting there do not fit my concept of a "radial flow" device. From the videos that I have reviewed, it seems to me that it is a vertical "AXIAL FLOW" device. That is another item for later discussion, but what I want to present to you is what I personally call a VERTICAL AXIAL SEPARATOR. The principle of the system is to drop out the muck and heavier solid matter exiting the pond or fish tank as a "prefiltration" unit, before routing the water to the other stages of the filter system (BIO-CONVERSION units).

My theory of the equipment operation is thus:

Water from the pond will gravity feed into the barrel chamber and rises up through a 2"-3" PVC tube to a level where the outlet of the tube meets a stilling "vat" or chamber that is open at the top - and bottom. The water does not overflow this stilling chamber, it slows in velocity and must redirect its flow to fall towards the bottom of the barrel, taking the heaviest sediments and debris with it. At the bottom of the barrel, the waterlogged and heavier sediments will collect and accumulate around the evacuation port (the drain) and can be exhausted when necessary by opening the valve.

Cleaner water, or that water that has lost its "load" must eventually rise to the outlet port, however, on its way, it will meet a baffle plate which will be constructed with several circular holes. These holes will be screened off with 300 micron SS fitler panels. Once the water passes through and reaches the top level of the barrel, it may pass through a perforated PVC standpipe, wrapped with finer mesh, cleanable, nylon mesh fabric (maybe 100 microns). This mechanical filter as well as the SS panels will all be designed to be easily removed and washed clean at periodic intervals - but the main duty of this first stage barrel is to "drop the muck" before it even gets to these fitler screens.

The principle of operation is exactly what Paul van der Werf explains in his radial flow filter videos, so I am applying that principle to the overal function of this barrel filter, yet adding my own DIY components to make it fit my own ideas.

The outlet or effluent water from this barrel filter will feed into the second mechanical filtration stage (another 55 gallon barrel). In that stage, I will incorporate ten - 50 micron nylon mesh filter socks to finish the job of large solids removal. These filter socks will also be easily removed and cleaned with a garden hose.

If you can discern the filter operation through my verbal description and the drawing I attached, let me know if you think that this filter is a good design or not.

Thanks,

Catfishnut