HTH, Well it looks like I found the wrong way to do this. After reading your post I thought I really should find a taller box. I go out and find a storage box that reads, crack free, gtd for life, unbreakable box and with more appropriate dimensions. Actually I bought two of them. Well the first one I filled up with water just to see how much it would bow under water pressure. It was a lot but after you mentioned extending the pond liner. I thought well I will just put it in the pond and that would solve the overflow problem and I really wouldn't have to worry about leaks. I thought the pressure from being in the pond would reduce the pressure on it enough that I wouldn't have to worry about how flimsy it felt. I dumped all but about two inches of water out of it. Reached down to pick it up and it tore. I thought well I can just return it good thing bought two of them. So much for unbreakable. These were about $8 compared to the truck box was about $40.

Went to the plumbing supply place where the guy behind the counter tries to sell me a brass connection to go from the 1'' on the pump to 1&1/2 pipe. Two plumbers who were in there suggested to go from a galvanized thread to a pvc bushing? this was about $8. I was slightly worried I could overtighten the galvanized pipe but it seemed to work ok.

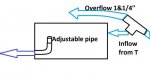

Drilled a hole in the box, heated up a knife, warmed the box a little and it cut like butter. Cut my pipes to length and a 2'' outflow with the pipe inside to set the height of the water as you mentioned. Hooked it all up and it promptly began to overflow the entire top of the container right back into the pond in a perfect waterfall. The outflow was working but not fast enough. Of course the sides bowed out so most of the water flowed around the matting. I have pictures of most things attached but I did not get a picture of this as I was pretty disgusted at that moment. Well I had just enough left over pipe that I raised it up out of the pond and set it on the side. Then I removed the length of pipe inside to set the water height and just left the elbow. The extra length of pipe and height reduced the water flow enough that it wasn't coming over the top of the container. However the volume of water returning to my pond looked like a hot tub. My fish were entertained and I let it run for an hour or so when I was out in the yard to clear the water up some because the old filter had been disconnected for a couple of days. I certainly didn't trust this set up enough to be left alone. Anyway I put it back in the pond with a much smaller older pump maybe 600 GPH. The design works but I was pretty set on using my new pump. So any suggestions. I was thinking either a bigger outflow. Or adding a second outflow. Or spitting part of the flow off before the input? Or using a bigger box and styrofoam like you suggested earlier? Lots of pictures attached. Thanks in advance for anyone input.