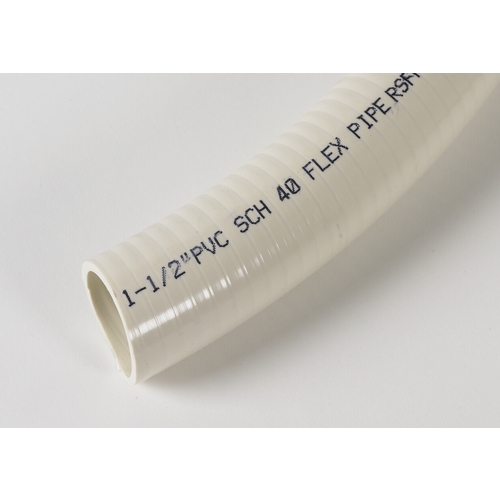

There are no connectors made for connecting that hose to PVC. There are connectors the manufacturer makes specifically for the hose but these are not meant to be water tight because the hose isn't meant to be used in a pressurized application.

To make it water tight you'd have to make your own using something like

silicone to make your own gasket. You need one for the inside between the PVC and hose, AND you need another for the outside between the hose and hose clamp. Without the gasket on the outside the clamp will deform the ribs and the gasket inside will leak. But this also requires using a smaller diameter PVC pipe.

Alternatives...

As far as stretching the hose over the PVC, good luck. It's easier to use a smaller PVC pipe and fitting to step up.

But if your heart is set on stretching. As you found, hard to do with a torch, its too hot. Can be done. Easier to use a heat gun. Or hot oil. I don't know the temp of that plastic becoming pliable, but probably in the 220-250F range. Heat the oil to the desired temp and put the end of the hose into the oil for say 30-60 sec. It's nice to have a cone shape piece of wood you can jam into the hose to stretch it. If you shove it onto the PVC it will cool and shrink and very kind of hard to get off, and pretty much impossible to then get back on. Chance of this not leaking are pretty low.

Or use a smaller diameter PVC pipe and the step up bushings and the goop of your choice. Again, tightening down the hose clamp is going to cause problems. The hose clamp you have is meant to be used with smooth wall hose. Goop once again may come to the rescue. For example some people use silicone caulk instead of the more expensive silicone mold stuff linked above. You should Google for the different ways this is done but generally you apply the silicone caulk and let it harden and then apply the clamp. Same for the inside gasket. But getting silicone to harden isn't that easy.

DIY vs smart

I'm not sure of the goal of this project. I'm a fan of DIY. I'll spend weeks doing DIY that could have been done in 10 minutes for 5% of the cost just because I want to see how something works. Like making plastic pliable and molding it. Yeah, the first few times it takes a lot of effort, but once you get the process down it's freakin cool.

Obviously for the cost of all the trips to Home Depot you could have flown in a plumber from Montana to replace the whole deal with the correct materials.

P.S. I don't remember the "al qaeda operative". I'll have to look it up.